padel court cover factory

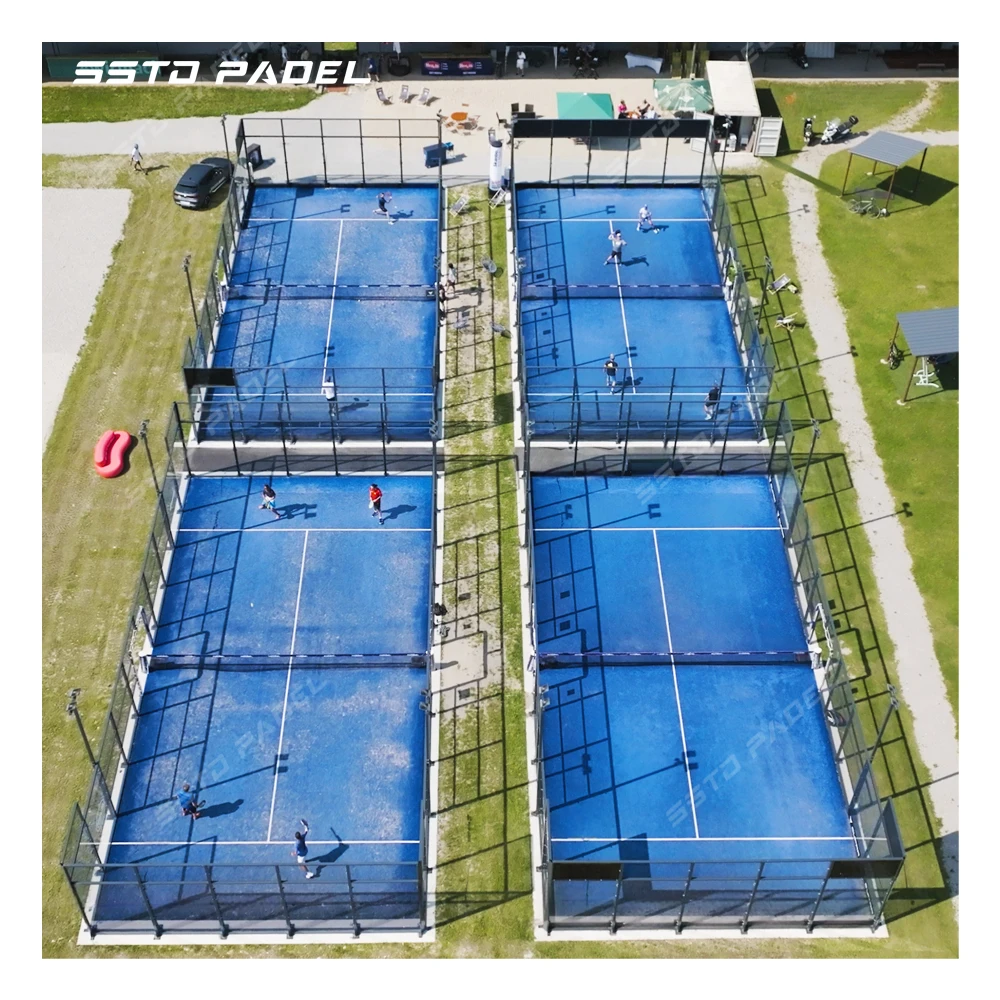

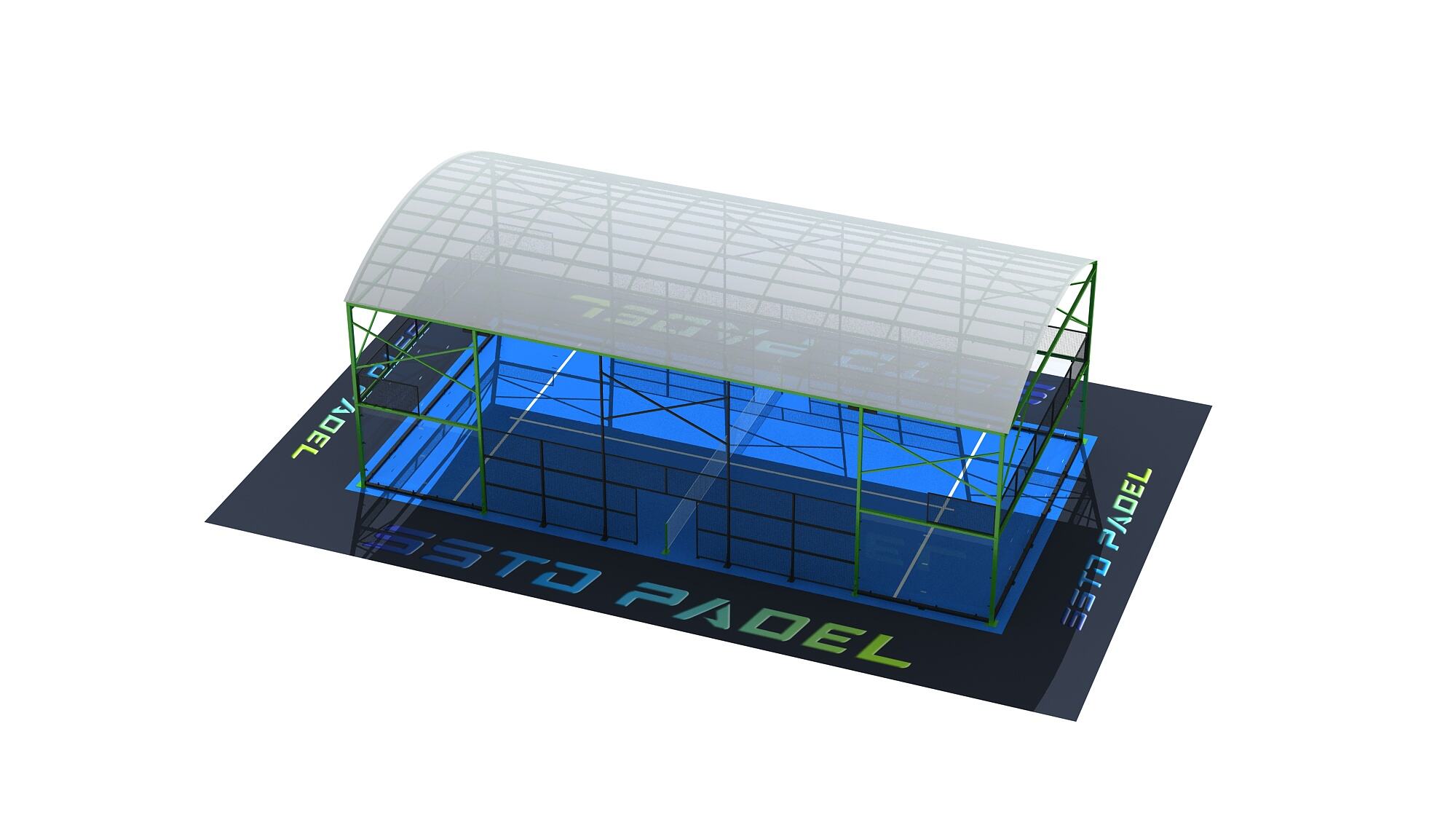

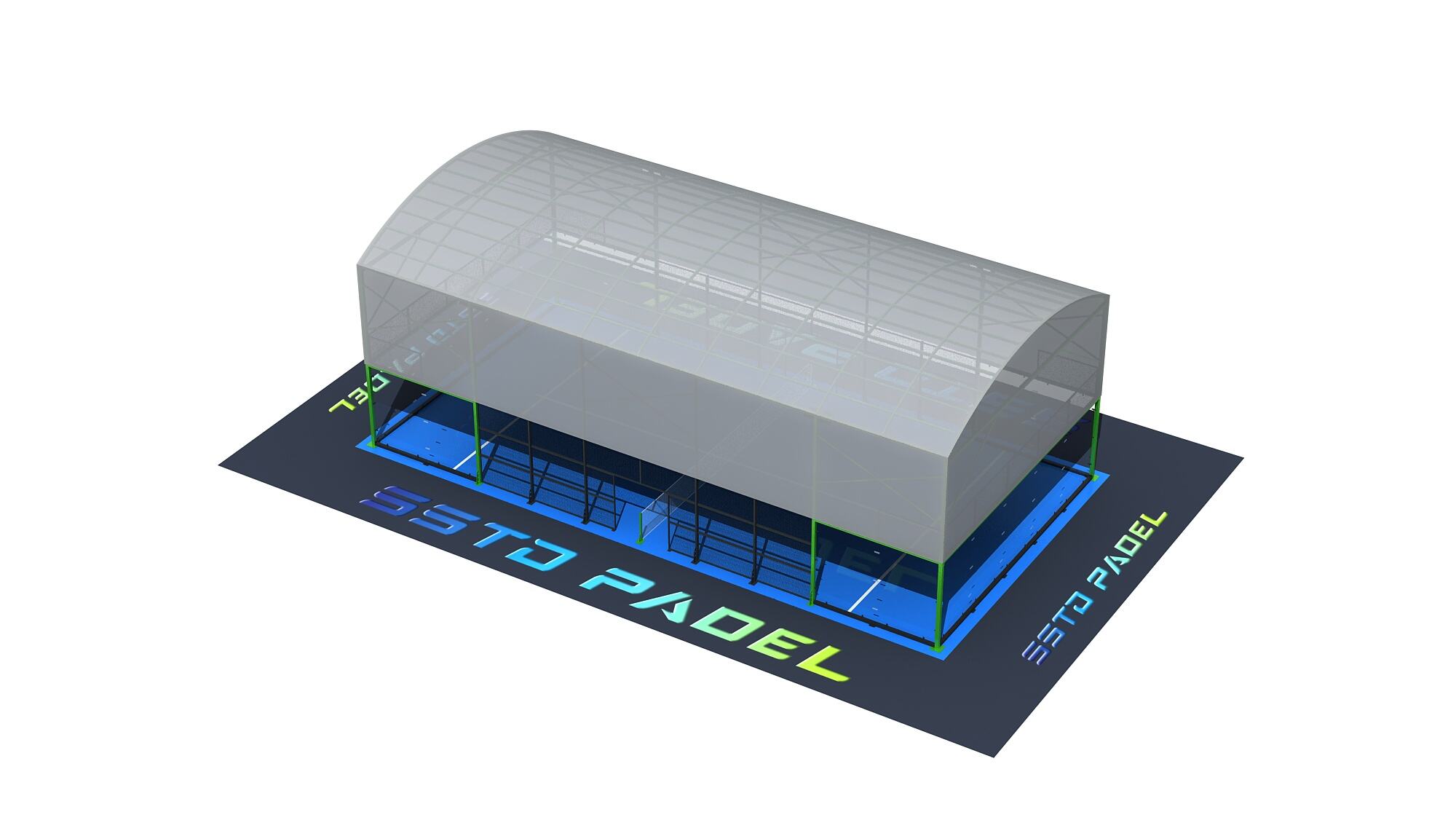

A padel court cover factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality protective coverings for padel courts. These specialized facilities combine advanced engineering with precision manufacturing to create durable, weather-resistant structures that shield padel courts from environmental elements. The factory utilizes cutting-edge technology and automated production lines to ensure consistent quality in every cover produced. Each manufacturing process is meticulously controlled, from material selection to final assembly, incorporating innovative design features that maximize protection while maintaining optimal playing conditions. The facility employs advanced quality control systems and testing procedures to verify the structural integrity and weatherproofing capabilities of each cover. Modern CAD/CAM systems enable customization of covers to match specific court dimensions and local climate requirements. The factory's production capabilities extend to various cover styles, including fixed structures, retractable systems, and modular designs, all manufactured using UV-resistant materials and corrosion-proof components. Environmental considerations are integrated into the manufacturing process, with energy-efficient equipment and sustainable material options available to meet growing eco-conscious market demands.