pink padel court factory

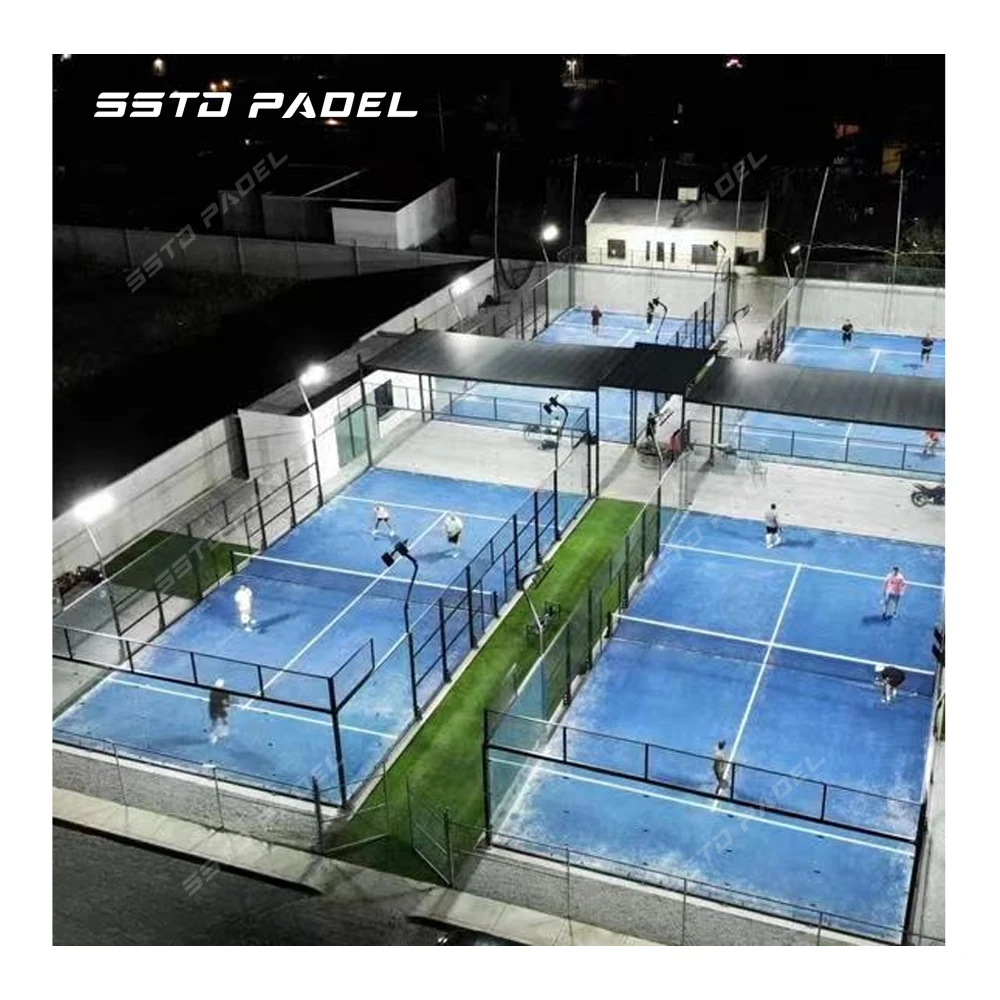

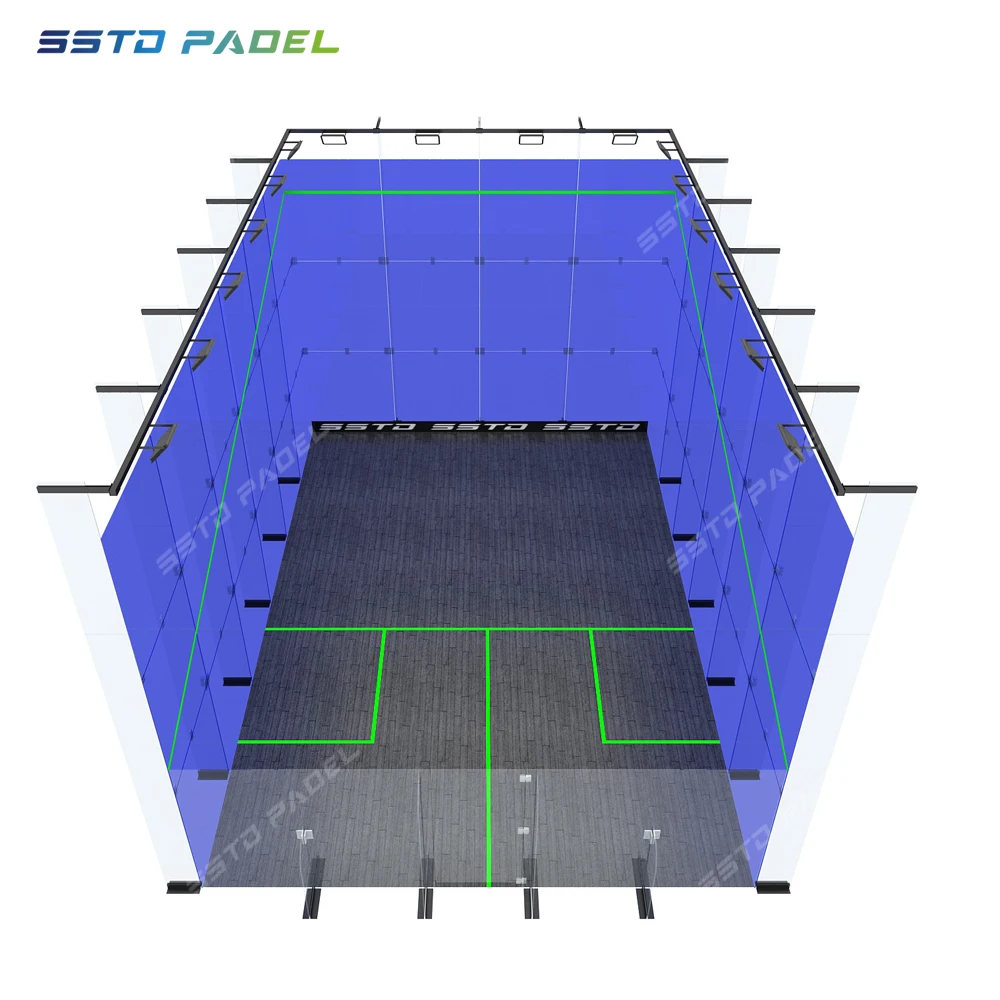

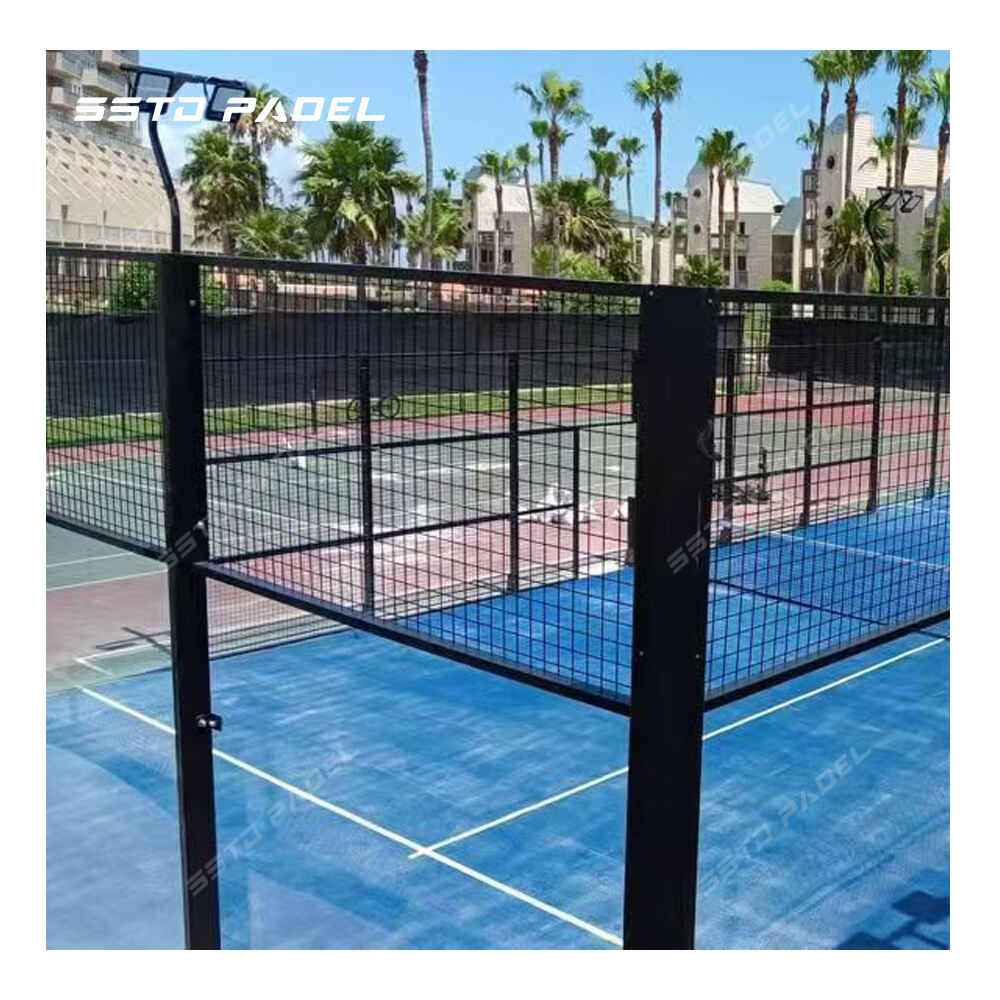

The pink padel court factory represents a cutting-edge manufacturing facility dedicated to producing premium quality padel courts with a distinctive pink aesthetic. This state-of-the-art facility combines advanced manufacturing processes with precision engineering to create courts that meet international standards while offering a unique visual appeal. The factory employs automated production lines equipped with robotic welding systems, powder coating stations, and quality control checkpoints throughout the manufacturing process. Each court is constructed using high-grade materials, including tempered glass panels, steel frameworks, and specialized synthetic turf designed specifically for padel play. The facility's production capacity can accommodate both standard and customized court designs, with the ability to manufacture up to 50 courts per month. Advanced computer-aided design (CAD) systems ensure precise specifications are met for every component, while the factory's innovative pink powder coating process guarantees long-lasting color retention and weather resistance. The facility also features an on-site testing area where completed courts undergo rigorous quality assessments to ensure they meet both structural integrity requirements and playability standards.